Description

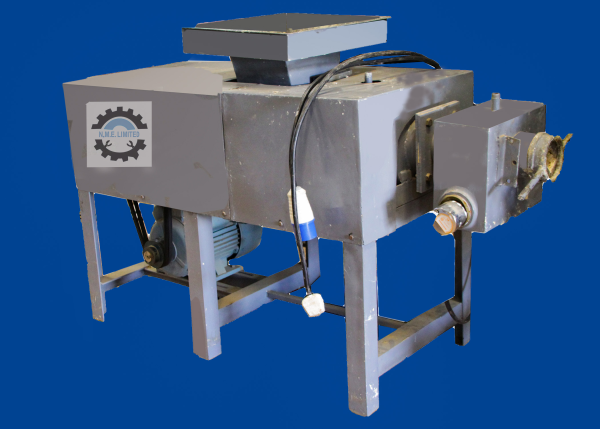

The soap plodder machine comprises a screw made in aluminium alloy, a jacketed barrel, a hopper to feed the soap from the incoming mixer, a gearbox and a basement. At the end of the plodder, there is a refining screen and a drilled plate assembled to extrude refined soap nodules. The soap then goes on to the soap cooling machine.

The barrel in our manual soap plodder is jacketed for cooling using a water chiller. The plodder releases vast amounts of heat when operated, and failure to cool it may reduce the production rate. The refining screen is a grid assembled before the drilled plate, and the screens are classified according to the number of wires per inch. Our plodder boasts a 30 mesh screen that grants a more considerable production rate and avoids soap heating.

The screw in our soap extruder has a useful length of up to 4 times the diameter. The length of the screw determines the efficiency of the plodder. A long screw with many spirals works the soap at high pressure, increasing the homogenization. This parameter is called the L/D ratio, where L is the useful length and D is the diameter of the screw.

You can also change the soap compression and production rate by shifting the shape of the screw. There are different types of screws: one with constant kernel diameter, one with increasing kernel diameter, one with a constant pitch, and one with variable pitch.

Main features

- Useful length of the screw: The plodder has a long screw with many spirals, which is over four times the diameter, guaranteeing higher efficiency.

- Refining screen: Our refining screen has a 30 mesh screen that grants a higher production rate since the grids are not too close.

- The shape of the screw: Our soap plodder allows you to switch the shape of the screw depending on your production needs.